Look around you. No, really, take a moment and scan the room you’re in. You might see the obvious—walls, a screen, maybe a window. But there’s a high probability you’re looking right at it without even seeing it. It’s the unsung hero, the quiet workhorse of our manufactured world, a material so fundamental we often forget it’s there. I’m talking about

woven wire mesh. It’s not just chicken wire or a screen door, it’s a technological marvel of interlocking wires, a metallic fabric engineered with a precision that would make a watchmaker nod in respect. From the moment you wake up to the second you drift off, this grid of metal is working tirelessly in the background, filtering your water, securing your home, and even helping build the car you drive. It is, quite literally, the fabric of our modern industrial life, a silent partner in progress.

The Art and Science of the Weave

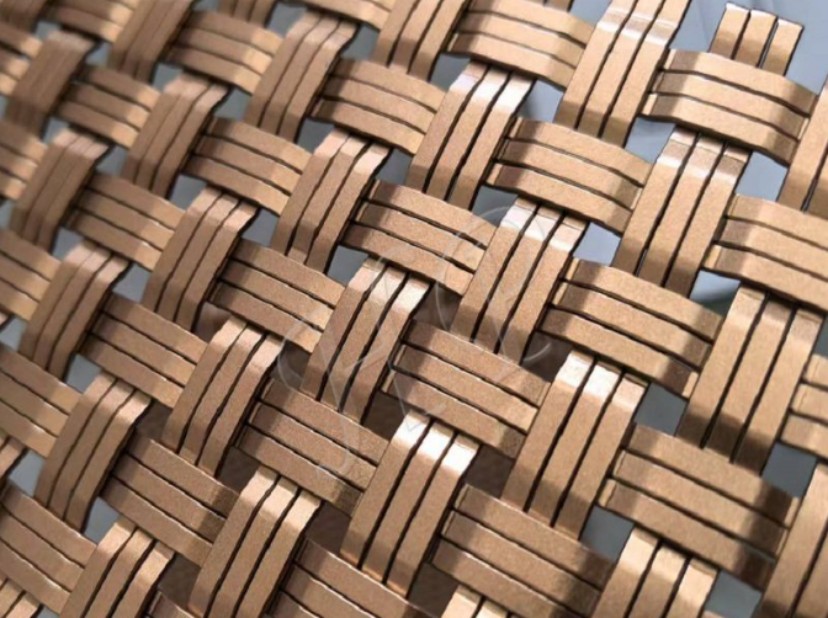

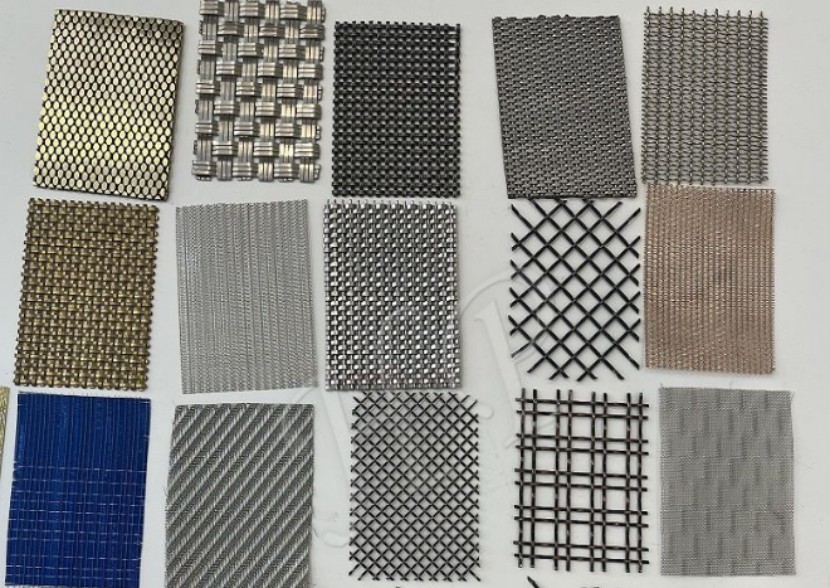

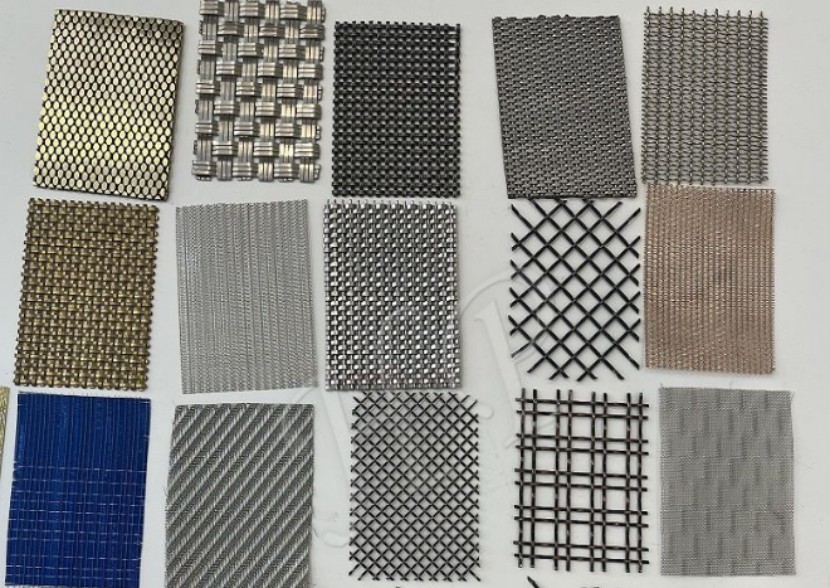

So, what exactly is this stuff? At its heart, woven wire mesh is exactly what it sounds like: a series of wires woven together on industrial looms, not so different from the ones used for textiles. But this isn’t your grandma’s knitting. We’re talking about a process that can handle everything from hair-thin stainless steel strands to robust, heavy-duty rods. The magic lies in the weave pattern itself. The most common one, the Plain Weave, is like the plain weave in a basket—each wire goes over one, under the next, creating a simple, strong, and square grid. It’s the reliable, all-purpose workhorse.

But then things get more interesting. Ever need a mesh that’s super strong but allows for a super smooth flow? Enter the Twilled Weave. Here, each wire passes over two and under two. This creates a distinct diagonal pattern, and it’s not just for looks. This structure allows for the use of thicker wires, creating a incredibly durable woven wire mesh that’s perfect for heavy-duty filtering or screening under serious pressure. And for the really fine stuff, the Dutch Weave comes into play. Imagine this: thick warp wires running lengthwise, with much thinner weft wires woven tightly between them. This creates a tapered, wedge-shaped filter that can trap particles far smaller than the actual mesh openings. It’s this kind of clever engineering that allows a woven wire mesh to separate things at a microscopic level.

Filtering the Flow of Modern Life

Let’s get down to the nitty-gritty, the places where woven wire mesh literally cleans up our act. Think about that first sip of coffee in the morning. The water you used? It almost certainly passed through a layer of woven wire mesh at the treatment plant, screening out debris and sediment before it underwent further purification. The beans themselves were likely sorted and graded using vibrating screens made of, you guessed it, woven wire mesh. And the oil you might cook your breakfast with? It was refined and clarified through massive industrial filters made from specialized woven wire mesh designed to handle high temperatures and corrosive chemicals.

This is where the material truly shines. In the chemical industry, a robust woven wire mesh made from stainless steel or exotic alloys acts as a guardian, ensuring that catalysts are the right size and that final products are free of contaminants. In the pharmaceutical world, the stakes are even higher. Here, a perfectly crafted woven wire mesh is used to sieve powders and granules for pills, guaranteeing dosage consistency and purity. There is zero room for error, and this metallic fabric delivers. It’s a silent, unwavering quality control inspector made of metal, working 24/7 in factories around the globe. Without this specific application of woven wire mesh, the consistency and safety of everything from aspirin to life-saving medications would be nearly impossible to maintain on an industrial scale.

The Unseen Shield Security and Separation

Now, let’s shift gears from what it lets through to what it keeps out. This is the more visible, but often overlooked, role of woven wire mesh. Walk through any major city and you’ll see it in the form of fencing and barriers. That elegant but imposing fence around a embassy? That’s not just for show, it’s a high-strength woven wire mesh designed to resist cutting and impact. The protective screen over the window of a corner store? It’s there to provide security without completely blocking light and air, a functional application of woven wire mesh that promotes safety while maintaining a connection to the outside world.

But the security goes beyond the obvious. Inside the walls of your home, a woven wire mesh acts as a reinforcing layer in stucco and plaster, holding everything together and preventing cracks from spreading. It’s a hidden shield against the elements and time itself. In construction, it’s used as safety netting, catching falling debris and protecting workers below. Think about a multi-story building under construction, the scaffolding is often lined with this material, a simple yet effective use of woven wire mesh that saves lives. It creates a safe perimeter, a secure boundary in a chaotic environment. Even in your car, a fine woven wire mesh might be protecting the radiator from rocks and road grit, a small but critical line of defense for your engine’s cooling system. It’s a guardian in a million different forms.

Building and Shaping Our World

The structural genius of woven wire mesh really comes to the forefront when we look at architecture and major infrastructure. This is where it stops being just a filter or a fence and starts being an integral part of the skeleton. Take gabions, for example. Those are the giant wire cages filled with rocks that you see holding back hillsides along highways or reinforcing riverbanks. The cage itself is a heavy-duty woven wire mesh. Its flexibility allows it to shift and settle without breaking, making it a perfect, resilient solution for erosion control and retaining walls. It’s a brilliant marriage of simple materials creating immense strength.

And let’s not forget design. Modern architecture has fully embraced woven wire mesh as a cladding material. Designers are using it to create stunning, dynamic facades on buildings. When used this way, the woven wire mesh can control sunlight, provide ventilation, and create ever-changing patterns of light and shadow, all while maintaining a sleek, modern aesthetic. It’s a testament to how a purely industrial material can be transformed into an artistic statement. Inside buildings, you’ll find it in decorative panels, balustrades, and even elevator cabs. This versatile woven wire mesh brings texture and a contemporary feel to interior spaces, proving that functional doesn’t have to mean boring. It’s a material that bridges the gap between the workshop and the art gallery.

The Future Woven in Wire

It’s almost dizzying to think about the sheer scope of what this one material does. We’ve followed its path from filtering the water and food we consume, to securing our spaces, and finally to holding the very ground beneath our feet together. The humble woven wire mesh is a foundational technology that continues to evolve. As industries push for finer filtration, stronger materials, and more complex designs, the demands on woven wire mesh will only grow. We’re already seeing it in advanced aerospace applications, in medical implants that allow bone tissue to grow through them, and in new forms of architectural expression.

The next time you pass a construction site, glance at a modern building facade, or simply pour a glass of water, take a second to consider the intricate grid of metal that likely made it all possible. It’s a testament to human ingenuity—taking a simple concept like weaving and scaling it up to an industrial, world-shaping level. This unassuming grid is a quiet testament to how we’ve learned to shape metal not just into beams and blocks, but into a flexible, functional, and indispensable fabric. The story of modern infrastructure, manufacturing, and security is, in many ways, a story written in the precise, interlocking threads of woven wire mesh.

But the security goes beyond the obvious. Inside the walls of your home, a woven wire mesh acts as a reinforcing layer in stucco and plaster, holding everything together and preventing cracks from spreading. It’s a hidden shield against the elements and time itself. In construction, it’s used as safety netting, catching falling debris and protecting workers below. Think about a multi-story building under construction, the scaffolding is often lined with this material, a simple yet effective use of woven wire mesh that saves lives. It creates a safe perimeter, a secure boundary in a chaotic environment. Even in your car, a fine woven wire mesh might be protecting the radiator from rocks and road grit, a small but critical line of defense for your engine’s cooling system. It’s a guardian in a million different forms.

But the security goes beyond the obvious. Inside the walls of your home, a woven wire mesh acts as a reinforcing layer in stucco and plaster, holding everything together and preventing cracks from spreading. It’s a hidden shield against the elements and time itself. In construction, it’s used as safety netting, catching falling debris and protecting workers below. Think about a multi-story building under construction, the scaffolding is often lined with this material, a simple yet effective use of woven wire mesh that saves lives. It creates a safe perimeter, a secure boundary in a chaotic environment. Even in your car, a fine woven wire mesh might be protecting the radiator from rocks and road grit, a small but critical line of defense for your engine’s cooling system. It’s a guardian in a million different forms.